Jewel Changi Airport is a new, 1.4 million-square-foot mixed-use hub and lifestyle destination at Singapore’s Changi Airport, one of the world’s busiest aviation facilities. The project opened this spring and has drawn acclaim for its unique design, highlighted by the world’s tallest indoor waterfall and a translucent, ovoid-shaped gridshell roof spanning 650 feet (200 meters) across. The building combines retail, restaurants, a hotel, and expansive indoor garden and leisure facilities, all publicly accessible and linked to airport terminals and Singapore’s public transit.

The project team includes design architect Safdie Architects, BuroHappold as roof building structure and façade engineers, and a group of leading international collaborators. Jewel is a true engineering marvel: its first-of-a-kind steel gridshell structure features a toroid ovoid shape, 200 meters at its longest by 150 meters at its widest, with a 12-meter opening at the center for the project’s indoor waterfall, known as the Rain Vortex. The gridshell is supported at the perimeter and at 14 internal columns; with only these intermittent supports, the result is a nearly column-free interior. Weighing 6,000 tons, Jewel’s gridshell comprises over 9,000 glass panels, 14,000 steel beams, and 6,000 connecting “nodes”— precision-fabricated steel connectors that make the diagrid roof system possible — all of which enable the central open oculus forming the 130-foot-tall Rain Vortex (Figures 1 and 2).

The full project team is as follows:

Consultants:

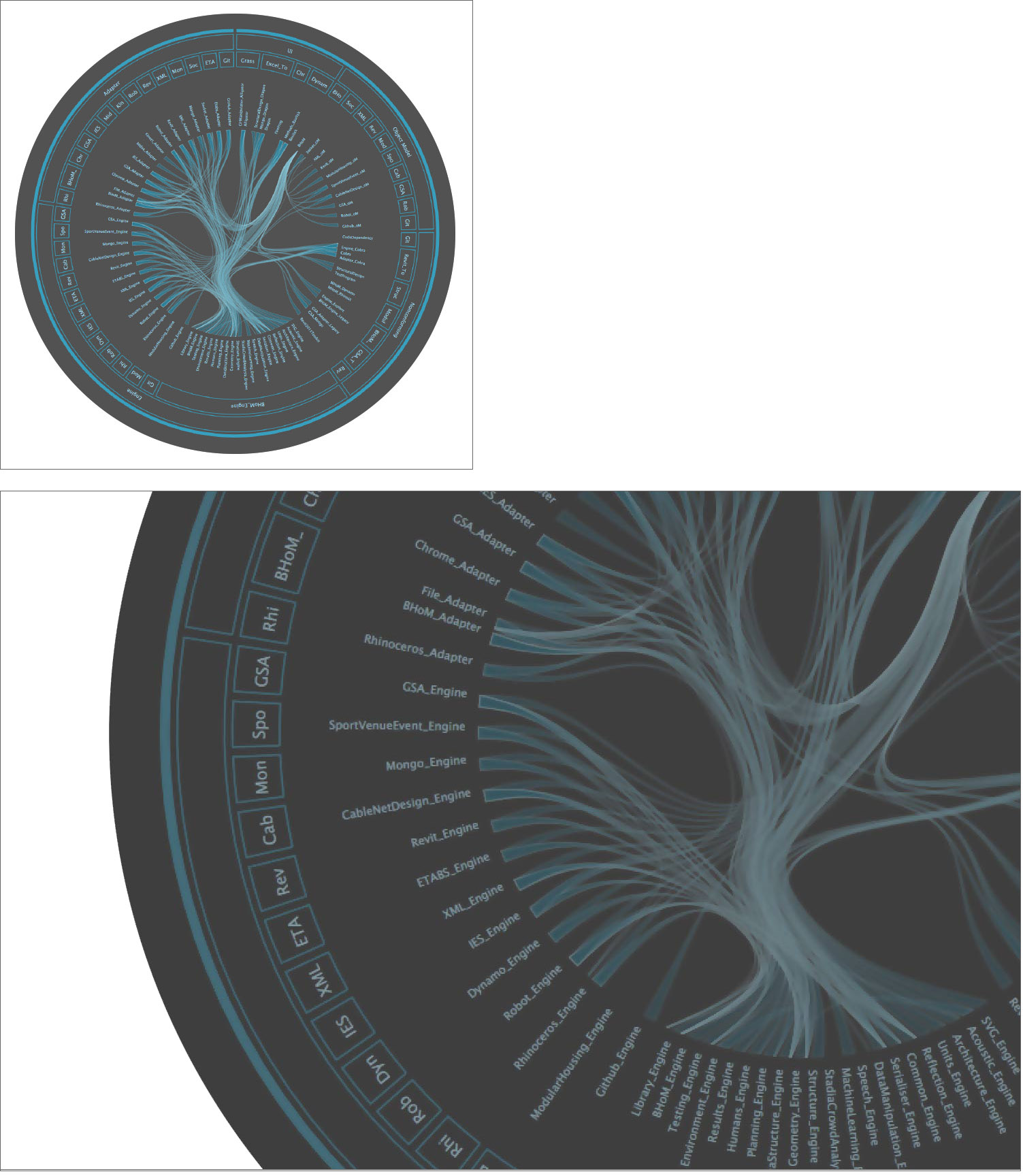

The engineering team used a number of advanced software applications and building information modeling (BIM) tools to optimize Jewel’s complex design. SAP2000 software allowed for experimentation with varying depths in the gridshell, as well as for rerunning analyses and adding material where needed (Figure 3). These analyses included elastic as well as inelastic behavior. OASYS GSA software enabled independent checks of these calculations. The engineering team also used Rhino for BIM and Grasshopper for the rapid generation of design alternatives.

Using these software programs dramatically improved the project team’s workflow. For example, Rhino allowed for simple interchanges of data between BuroHappold and the designers at Safdie Architects. By creating scripts in Grasshopper, BuroHappold could then manipulate these shared files, generating geometrical files that identified structural steel elements and could also be imported into the SAP2000 software for analysis. After the elements were sized, they could be evaluated in Rhino.

Eventually, those Rhino files were used to create a 3D extruded model in Revit that would be used as the basis for structural drawings. It’s a complex back-and-forth, but advanced software eased the way.

From an application perspective, the key technology approach was to use software parametrically. The geometry for Jewel’s structure was highly complex, and it changed often during the design process. Different shapes and discretizations frequently came under review, analysis, and evaluation (Figure 4). The engineering team had to deal with a very large amount of information, so it was necessary to develop an approach that could rapidly synthesize meaningful insights to the behavior of the gridshell structure. A parametric approach allowed the engineering team to make changes to the gridshell form that could more readily be incorporated into the design flow.

Absolutely. Jewel demonstrates the feasibility of designing a complex form with a single set of rules, but also with variation in the shape of each “node” and individual element. The BIM files allowed for significant probing of the variation in the different element geometries, which enabled the engineering team to understand how the connections would be constructed. This information also allowed the architect to create realistic renderings of these details, and was later used to fabricate the physical pieces that make up Jewel’s totally unique form.

From a technology and software perspective, the project’s scale and complexity formed a central challenge. The large size of the design and analysis files meant more time was required for analysis and optimization. For example, some of the models had 14,000 individual elements. Wherever possible, we automated the process of going between rendering files (for the architects) and analysis files (for the engineers), to allow for a more rapid evaluation of different options.

The designers were conscious that the different bidding fabricators would use their own proprietary technology to improve and propose better ways of achieving the design. With that in mind, we focused on realistic options while at the same time leaving the door open to fabrication technologies that we thought might be used.

Jewel benefitted greatly from a collaborative environment that resulted after the design was successfully bid out (Figure 5). The ultimate result of this collaboration was a design that was not only beautiful but also buildable and affordable. Thanks in large part to the project team’s innovative use of AEC software and technology, the designers were able to work productively with the contractor, Mero, to achieve Jewel’s unique architectural vision using that firm’s 3-D computer-numeric controlled (CNC) milling technology.

Acknowledgments: The responses to the questions for this profile were provided by Cristobal Correa, PE MSCE BSCE, Principal, structures, BuroHappold. The profile was facilitated by Alex Abarbanel-Grossman of C.C. Sullivan.

Have comments or feedback on this article? Visit its AECbytes blog posting to share them with other readers or see what others have to say.

AECbytes content should not be reproduced on any other website, blog, print publication, or newsletter without permission.

Copyright © 2003-2026 AECbytes. All rights reserved.